Equipment Capacity and Capabilities

Facility

- State-of-the-art facility

- 75,000 square feet dedicated to manufacturing space

Forming Equipment - all forming advanced thermoplastics in sizes noted

- Thermoforming Machines

- Maximum sheet size 60" x 108", Maximum forming temperature 650° F

- Thermo/Pressure Forming Machine

- Maximum sheet size 48" x 76", Maximum forming temperature 650° F

- Performs pressure forming to give sharp detail

- Forming Station

- Maximum sheet size 48" x 72", Maximum forming temperature 650° F with adjustable air cylinder assist

- Manual Forming Station

- Maximum sheet size 48" x 48", Maximum forming temperature 650° F

Forming/Laminating Press

- 700 Ton Press with Heated Platens

- Platen size 48" x 96" x 48" daylight and stroke

- Maximum temperature 600° F

- Thermanoil cooling system

- Laminating processes and composite crush-core operations

- 400 Ton Press with Heated Platens

- Platen size 50" x 80" x 48" daylight and stroke

- Maximum temperature 550° F

- Thermanoil cooling system

- Laminating processes and composite crush-core operations

- 100 Ton Press

- Platen Size 24" x 28"

- Maximum temperature 600° F with cooling capability

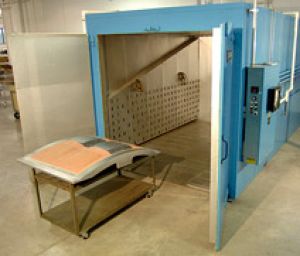

Processing Ovens - curing, heat setting and laminate stripping operations

- Walk-in Processing Ovens

- Capacity 4'W x 5'H x 5'D and 8'W x 6'H x 8'D

- Maximum Temperature 500° F

CNC Machining Equipment

- 5 Axis CNC Routers

- Machining capacity 60" x 120" or dual 60" x 60" x, 29"Z, 18,000 RPM

- Consistent, quick, high-tolerance trimming of plastics, composites and sheet metal

- 4 Axis CNC Router

- Machining capacity 60" x 120"or dual 60" x 60" x 11"Z, 16 HP, 18,000 RPM, 12 (ATC)

- Consistent, quick, high-tolerance trimming of plastics, composites and sheet metal

- 3 Axis Machining Centers

- Machining capacity 48" x 96"x 18"Z, 25 HP, 8,000 RPM, 30 (ATC)

- Machining capacity 25" x 40" x 25"Z, 30 HP, 12,000 RPM, 24 (ATC)

- Machining capacity 20" x 30" x 20"Z, 30 HP, 12,000 RPM, 24 (ATC)

- Aluminum/steel mold making, plastics, composites and sheet metal trimming

Heat Vacuum Applicator

- Laminating capacity 60" x 96"

- For application of laminate to new and refurbished sidewall panels, bin doors and other flat or contoured surfaces

Die-Cutting Equipment

- 80" x 115" Double Sided Flat Bed Die Cutter

- Cutting capacity 70" wide x continuous

- Clicker Press

- Heavy-duty platen press with sliding table specially designed for kiss cutting

- Capacity; 30" deep x 34" wide

- Pressure; 35 tons with 8" stroke and 19" daylight

Additional Equipment

- Pre-Preg Sub-zero Storage Freezer 8' x 8' x 8'

- Hydraulic Shear: Max. shear width 108"

- Manual Press Brake: Capacity 48" x 16 gauge

- Table Saws (2)

- Shapers (3)

- Table Routering Stations (2)

- Band Saws (4)

- Panel Saw (2)

- 24" Double Disk Sanders (2)

- Drill Presses (4)

- Index Mills (2)

- Turning Lathe

- Surface Grinder

- Ultrasonic Welders (2)

- Welding equipment

- Down Draft Bonding Table: 48" x 84"

- Reciprocal Spindle Sander

- Planner

- Jointer

- Mixing, Shaker equipment

Special Process Rooms

- Pattern Shop / Epoxy Casting Center

- Capacity 30' x 50' for prototypes, tooling and fixtures

- Ventilated Coating/Spray Room

- Capacity 18' x 24' for painting and applying other coatings

- Ventilated Sanding Room

- Capacity 18' x 24' for preparing panels for laminate recovery or painting

- Climate Controlled Ventilated Assembly/Lay-up Room

- Capacity 26' x 43' for bonding, composite lay-up and silk-screening

Operating Systems

- Computer Aided Machining

- Mastercam X6

- Engineering

- Catia V5 and Design X

- SmartTeam document management

- Catia V5 and Design X

- Business

- JD Edwards Business System with MRP

- Manufacturing facility computer terminals for processing orders and accessing drawings

- EDI processing capabilities